Computational Modeling and Simulations

NREL applies powerful multiscale computational modeling and data science to accelerate bioenergy and bioeconomy research and development.

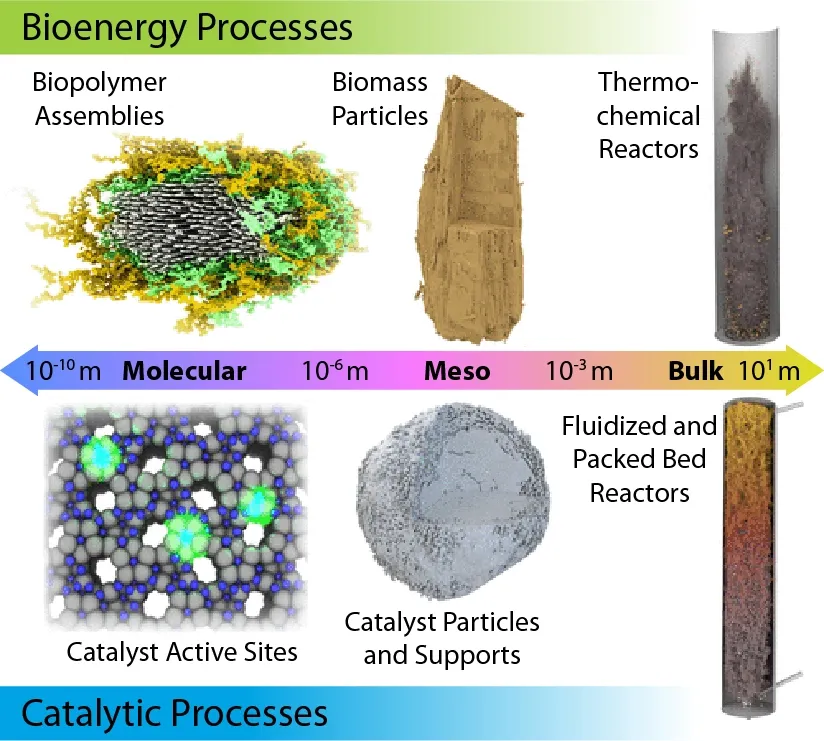

Depiction of molecular, meso-, and bulk modeling regimes encountered in the context of thermochemical bioenergy processes (top) and catalytic processes (bottom). These conversion technologies require careful control over molecular-level chemical transformation events, which are tightly coupled to transport phenomena within hierarchically porous particles subjected to multiphase hydrodynamics in various reactor configurations.

We apply these capabilities, including machine learning and artificial intelligence, to fundamental scientific questions, such as elucidating the molecular-scale structure/property/function relationships in plant tissues, bio-based materials, and enzymes. They also support applied projects with industry partners, such as reactor modeling process scale-up and optimization.

Our researchers work closely with experimental teams from academia, industry, and other national labs to develop, validate, and apply computational tools to deliver impactful solutions to the unique challenges associated with bioenergy and catalytic processes and adding value to waste materials.

Key Capabilities

Key computational modeling and simulation capabilities include:

- Density functional theory for modeling reactive processes in biological and chemical catalytic systems

- Molecular dynamics, with specific expertise in (bio)-polymers and their natural and synthetic composites

- Mesoscale modeling of reactive transport processes in nano- and micro-structured systems, including biomass particles, formed catalysts, and structured electrodes

- Direct import of 3D image data (e.g., X-ray and electron tomography) for detailed and accurate representation of system geometry

- Kinetic model development and computational extraction of kinetic parameters from experimental data

- Computational fluid dynamics (CFD) simulations for process scaleup and reactor design and optimization

- Machine learning and artificial intelligence, with a focus on applying these methods for functional protein and enzyme design, multiscale coupling, and reduced-order model development.

Molecular dynamics simulation of mechanical disruption of plant secondary cell wall components. Video by Lintao Bu, Meagan Crowley, Michael Crowley, and Peter Ciesielski, NREL

Mesoscale simulation of convective fluid transport through the microstructure of Douglas fir wood in the radial direction. Adapted from Measurement of Transport Properties of Woody Biomass Feedstock Particles …, Frontiers (2022)

Collaborations

Learn more about NREL's contributions in computational modeling and simulations within consortia:

CCPC: Consortium for Computational Physics and Chemistry (U.S. Department of Energy)

CO2Rue: CO2 Reduction Upgrading for e-Fuels Consortium (U.S. Department of Energy)

FCIC: Feedstock-Conversion Interface Consortium (U.S. Department of Energy)

ChemCatBio: Chemical Catalysis for Bioenergy Consortium

Center for Bioenergy Innovation (Oak Ridge National Laboratory)

Collaborative projects include:

CCPC: Atomic-Scale Computational Modeling

CO2RUe: Multiphysics CFD for Design and Scale-Up of Gas Bioreactors That Utilize CO2, DOE Presentation (2023)

Significance and Impacts

Computational modeling and simulations of energy technologies enable rapid prototyping, design and process optimization, physical insights and discoveries, and reliability engineering. This critical research supports the rapid development and reliable deployment of more efficient and affordable energy technologies. Added benefits include enabling scientists and engineers to test systems without the risk of expensive equipment or processes that may not work as intended.

Contact

Share

Last Updated Sept. 11, 2025